Search

0512-6255 1277

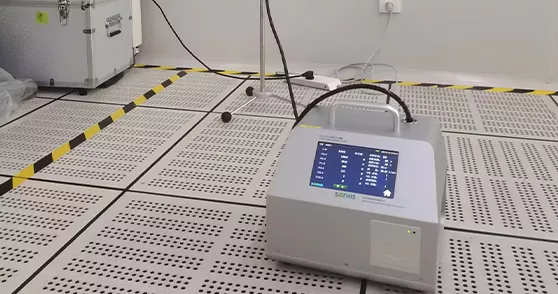

Sothis (Suzhou) Environment Technology Co., Ltd. specializes in providing integrated intelligent operation solutions for controlled environments. Its hardware products include particulate sensors, various environmental monitoring instruments, localized purification equipment, and consumables. The company offers end-to-end services encompassing research and development, design, supply chain management, sales, verification, and testing, all rooted in clean technology applications. To better serve its clients, in 2024, the company achieved the capability to test 58 parameters related to four categories of products—air volume control valves, air outlets, silencers, and filters—as well as cleanroom systems.

We specialize in testing cleanroom environments—including particle concentration, temperature and humidity control, and pressure differential management—as well as equipment performance for clean benches, biological safety cabinets, air showers, and pass-through windows. Our assessments ensure compliance with production standards, stable equipment operation, and enhanced product quality and safety.

Cleanliness testing in electronics and semiconductor workshops is crucial to maintaining high production standards. This process involves monitoring airborne particles, microorganisms, and other environmental parameters in accordance with international standards such as ISO. By combining dynamic and static testing methods, we assess the cleanliness of the workshop, ensuring product quality, compliance with production regulations, and optimization of manufacturing processes.

Our experienced team utilizes advanced numerical simulation techniques to accurately model complex physical processes, such as airflow patterns and temperature distribution, in cleanrooms and HVAC systems. This predictive and optimization approach allows us to identify potential issues early, reduce design risks, and enhance system performance and energy efficiency.

Our experienced team utilizes advanced numerical simulation techniques to accurately model complex physical processes, such as airflow patterns and temperature distribution, in cleanrooms and HVAC systems. This predictive and optimization approach allows us to identify potential issues early, reduce design risks, and enhance system performance and energy efficiency.

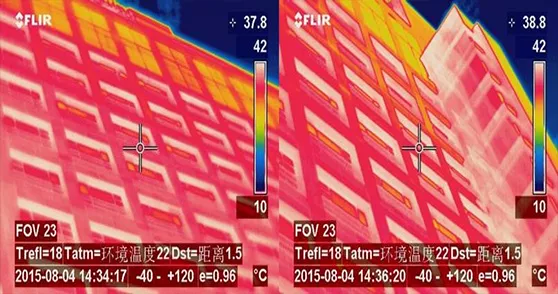

We conduct in-depth analysis of energy consumption data for enterprises or facilities to identify peak usage periods and inefficiencies. By comparing energy variations across different timeframes and operating conditions, we assess the effectiveness of energy-saving measures. Based on these insights, we provide robust support for developing scientifically sound energy management strategies.

Submit the form below to contact us now.